Lighting the Way

GOTEC needed to establish itself as a leading design house for LED lighting products and improve management of product information throughout its development process.

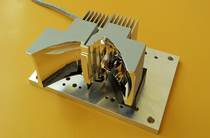

In an environmentally conscious world, the advantages of LED (light-emitting diode) technology are apparent. LEDs last longer, consume less energy, and are more robust than traditional incandescent light sources. LEDs abound in everyday products and are considered by many as the lighting technology of the future. Among those believers is GOTEC, s.r.o., a Czech company established in 2011 with a clear mission: to develop automotive LED lighting that marries good looks with advanced technology.

“We are increasingly seeing shapes for automotive lighting that would, a few years ago, seem unimaginable because they weren’t mainstream,” Vladimir Dobrus, Managing Director, GOTEC, said. But times are changing, according to Dobrus, who says vehicle lighting style has become a major focus of automotive manufacturers on a par with the look of the car itself. “It enhances the pleasure of owning a beautiful car,” he said. “Automotive OEMs require stylish lighting that attracts the eye and that can be tailored to define a car brand’s signature. So when we created GOTEC, we knew that flexibility would be the key to our success. And to have design flexibility, we knew we would have to equip ourselves with powerful technology that would enable us to design the different types of lighting our OEM customers want.”

Becoming a player with 3DEXPERIENCE

The wide range of styling possibilities permitted by LEDs has opened the door to a new level of creative innovation upon which GOTEC is building its reputation. The company is staffed with designers and engineers who have gained valuable expertise in lighting design, optics, electronics, CAE analysis and prototyping throughout a decade of working for various automotive design offices in the Czech Republic. “There is a shortage of people who have LED design experience and we at GOTEC intend to fill in this gap,” Dobrus said.

“As a young company, our major challenge is to convince potential customers that we have the required expertise and experience to provide them with the best possible solution. This is one of the reasons we chose Dassault Systèmes’ 3DEXPERIENCE technology, including CATIA for our lighting design work. It’s powerful and flexible and adapts to our way of working instead of the other way around,” Dobrus said. “It’s also the solution many of our customers and partners use, which facilitates collaboration and data exchange.”

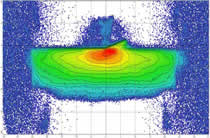

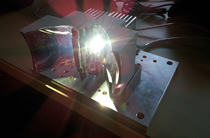

With CATIA for Creative Designers, GOTEC does product and optical design as well as testing in a virtual environment. “Our customers provide us with automotive body designs that we incorporate our lighting designs into. This enables us to ensure proper fit and overall harmony of the finished product early, which eliminates costly surprises that can arise during the manufacture and assembly stages. We are on our way to eliminate physical prototypes since our engineers perform kinematic analyses and interference checks on the 3D digital mock up. This is an environmentally sound choice, which is coherent with the very nature of an LED-powered product,” Dobrus said. CATIA also gives GOTEC the freedom and flexibility to create any complex shape, which results in some interesting lighting designs.

Fully aware of the importance of product lifecycle management and collaboration, GOTEC selected ENOVIA Version 6, the collaborative innovation base of Dassault Systèmes’ 3DEXPERIENCE Platform. “Managing the entire lifecycle of our products is a must when it comes to design reusability and traceability. We had some experience with PDM systems in the past but they were not up to the task of supporting our need to work in a global environment with international customers. A process and lifecycle management approach is in order if we want to establish our reputation as a serious player. This is why we chose the robust and open architecture of ENOVIA Version 6.”

Increased traceability, innovation and faster time to market

“All our employees are connected to ENOVIA. We are already using it for data management, to manage BOM and engineering changes, as well as for role-based project management. “We will also use the PLM system to create libraries for standard parts and to manage the requirements of our customers and partners and for document management within the company,” Dobrus said. “And just recently we were trained on 3DVIA Composer, which we use to create all our technical and marketing presentations.”

Experienced partner

When it came to choosing a partner, GOTEC selected 3DS partner Dytron. “We selected and closely collaborated with Dytron because of its excellent technical experience and our two companies’ personal relationship,” Dobrus said. Dytron has been responsible for the delivery and implementation of GOTEC’s complete IT infrastructure, virtual product design, authoring tools and PLM system including technical support for the installation of the 3DS solutions.

According to Dobrus, GOTEC’s plans for the future include collaboration with partners, which will further reduce time to market and drive innovation since ideas can be more easily exchanged and tested online in real-time. “Already our employees perceive noticeable gains with the 3DS applications,” he said. “They can visualize their ideas and test designs very early during the development process. And with its advanced functionality and intuitive usability, the 3DS technology has increased design and engineering efficiency. It is a considerable step forward as we try to make a name for ourselves in the growing LED business,” Dobrus concluded.

For more information visit the website.

Images courtesy GOTEC s.r.o.