How does microroughness impact optical performance?

Optical Surfaces has undertaken a study to determine how microroughness impacts the performance of Aspheric lenses and mirrors. Microroughness is a quantity which considers features which are even smaller than slope errors and is often expressed in RMS terms after integrating over spatial periods that are usually less than 0.25mm.

Such features, when pronounced, tend to cause effects that may be compared to mild scattering. For many applications such effects may not be so critical. However, for high power laser applications using mirrors or lenses as key focusing elements these effects can play an important role and therefore microroughness needs to be well controlled.

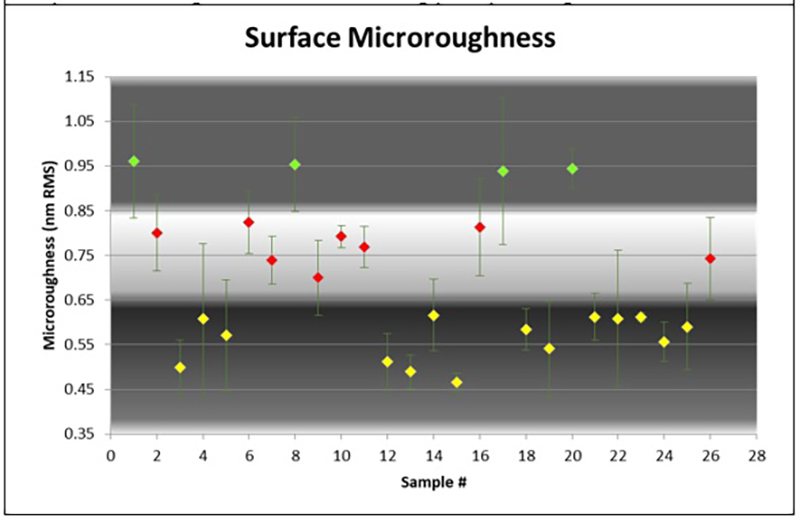

Although it is not fully understood, Optical Surfaces has found that microroughness can be controlled during manufacturing using a pitch-polishing technique which regularly produces very good results that consistently do not exceed one nanometre RMS.

Data is presented on a selection of microroughness measurements performed on over 25 high precision aspheric optics manufactured by Optical Surfaces in recent years. Some evidence is shown that the more challenging optics, that manifest higher asphericity, are the ones that exhibit microroughness closest to one nanometre RMS.